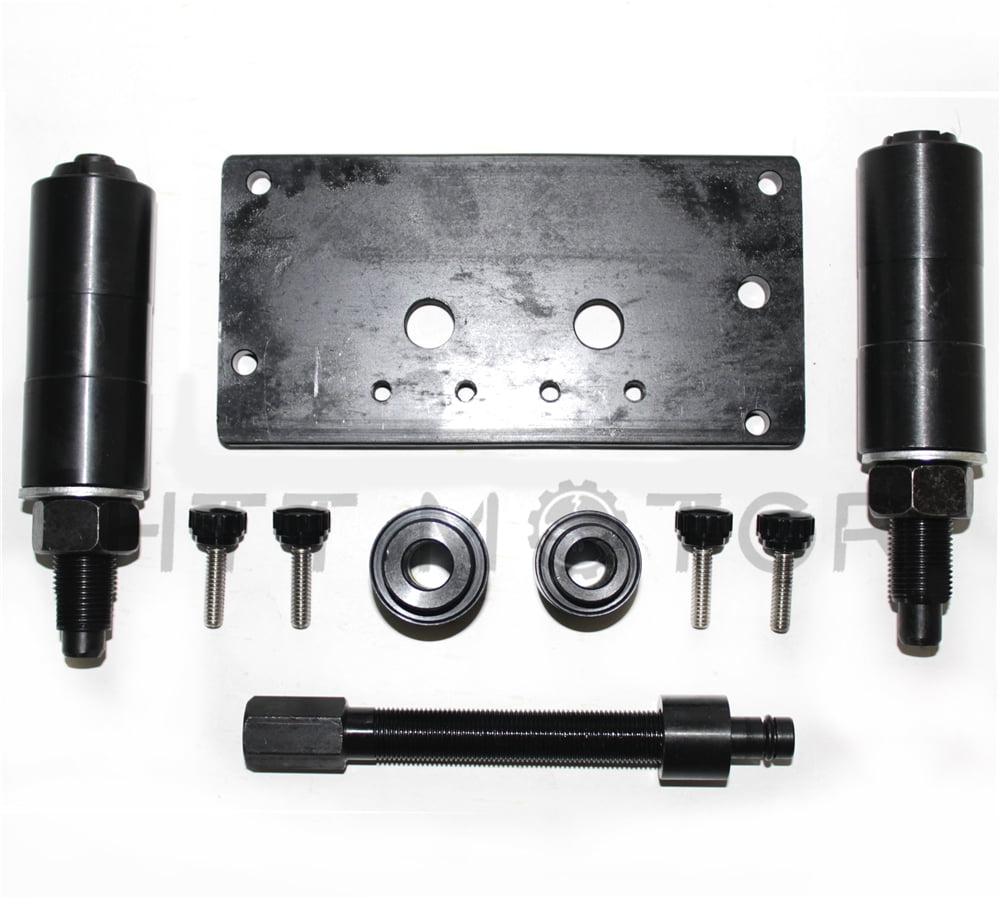

Re-machine value guide bores and finish value seats to different performance specifications.Machine value spring pockets for oversize springs.We choose to use the Peterson (left) because this rigid machine is known for its heaviness and durability. As long as bearings and races are available we are able to rebuild units to new specifications. Motorcycle Machine Shop Services offers a complete line of crank shaft rebuilding services for all models and years of Harley Davidson’s and after-market V-twin engines. Harley Davidson female connecting rod (below) being touched off after installing new bearing races for rod rebuilding. It has a 2 inch thick table and blancher grounds, which is designed for all aspects of V-twin boring. Our boring table, equipped with 2 Van Norman 777S boring bars, was manufactured in-house. Take a look at some of our equipment and current projects below. Motorcycle Machine Shop Services is a complete jobbing shop where we manufacture our own tooling, fixtures and jigs. Run out on sprockets will be held within. Will come with all spacers and necessary parts. Can be used with 330, 360 or 410 tire bikes. If you need a new exhaust stud drill plate, a pin clip remover, a mainshaft sprocket locknut wrench or a new fork and leg tube holder, the place to find them all (and. Off set sprockets for 530 or 630 chain, 23 or 24 tooth other sizes available –įrom 1 3/8 inches to 4 inches for wide tire applications. If you think you can walk into any hardware store and find Specialty Tools for your motorcycle - especially JIMS - you’re sorely mistaken. We have serviced our customers in the greater Ft Lauderdale area since 1990.

#Harley evo camshaft degree tool full

Motorcycle Machine Shop Services is a full service Harley flywheel, Harley crankshaft, Evo flywheel & Shovelhead rebuilding machine shop specializing in Harley Davidson motorcycle engines and aftermarket parts. Reassemble cases and torque bolts to factory specs.

#Harley evo camshaft degree tool install

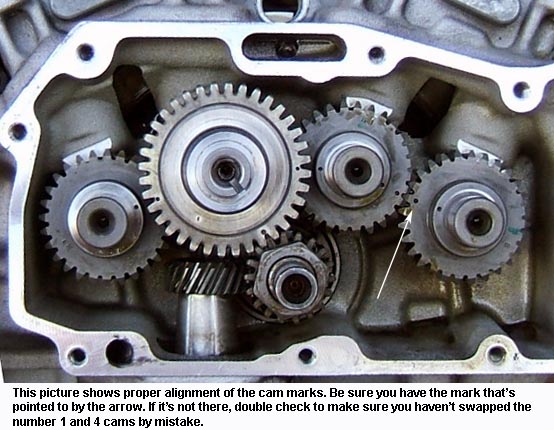

Install crankshaft with new sprocket bearings, pinyon bearings, cam bearings, inner and outer counter shaft bearings and sprocket seal. Rebuild crankshaft with new crank pin, bearings, races if needed, honed to proper clearance and true crankshaft.

Reassemble cases and torque bolts to factory specs.ĭisassemble, clean and inspect all parts. Install crankshaft with new sprocket bearings, pinyon bearings, cam bearings and sprocket seal. Pan flat head and sportster short block rebuilding –ĭisassemble, clean and inspect all parts. Set end play on sprocket bearings and reassemble and seal case and torque all case bolts. New cam bearing install crank shaft with new sprocket, shaft bearing and races. Rebuild crank shaft with new or rebuilt rods, line hone pinion bearing race. Disassemble, clean and inspect all parts.

0 kommentar(er)

0 kommentar(er)